Customized protection helmets

Low impact absorbing helmets

The story

Traditional custom protective helmets have long been labour-intensive and slow to produce, requiring plaster casting, manual shaping, and multiple fitting appointments. This not only extended delivery times but also made it challenging to achieve a consistently excellent fit and comfort. For patients who wear helmets all day, sweat and moisture can accumulate, making cleaning and maintenance a constant effort.

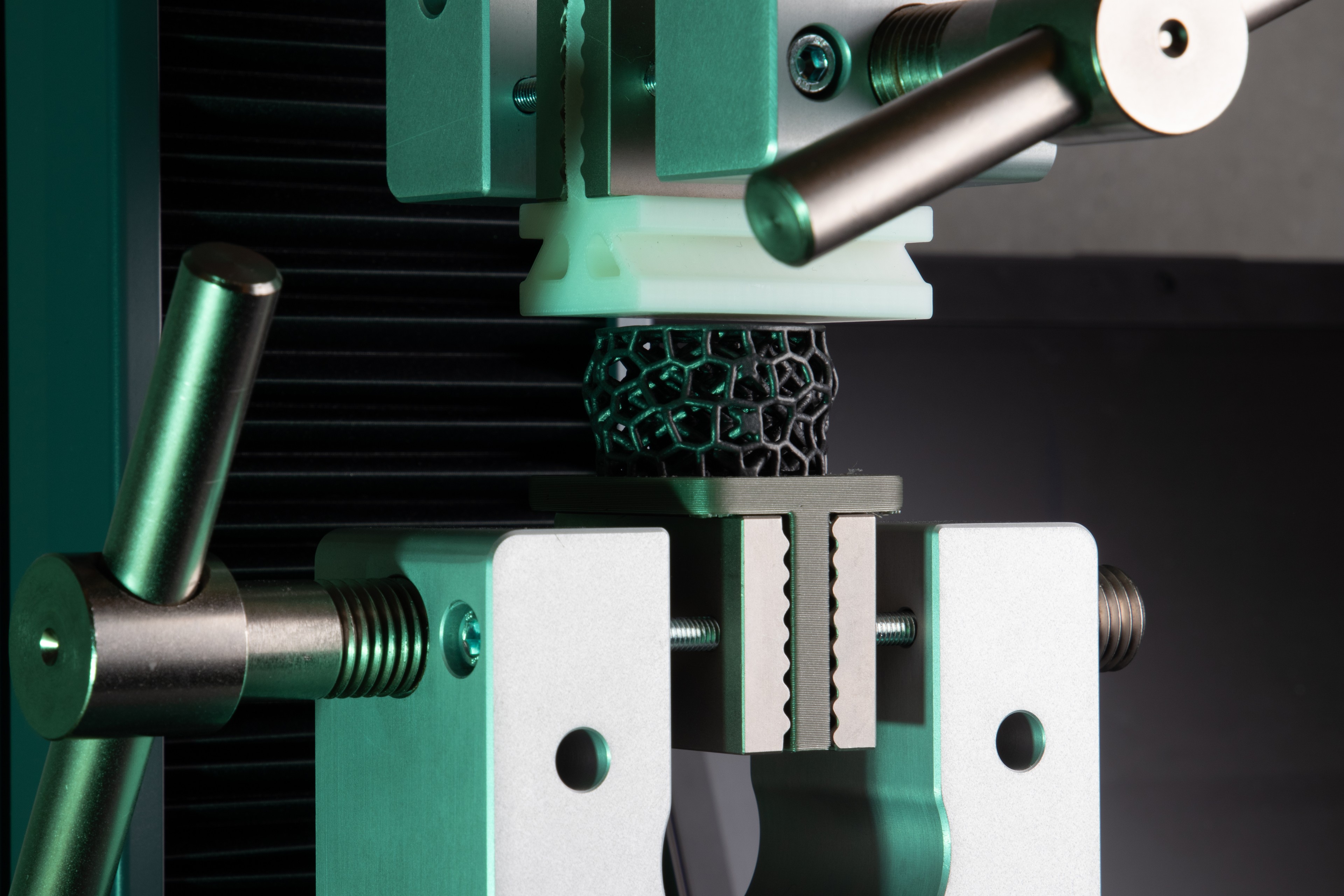

The OrthoSolid protection helmet offers a modern solution for low-impact protective headgear. By taking a simple 3D scan and uploading it to the OrthoSolid platform, clinicians can create a custom helmet with minimal effort. Its open, ventilated design promotes airflow, while integrated buffer structures — printed in a single piece — provide consistent support and make cleaning quick and easy. The result is a helmet that is both patient-friendly and clinically reliable.

The benefits

Time efficiency

A streamlined from patient intake to delivery. A quick 3D scan replaces traditional casting, and the helmet is created without manual work. This digital process eliminates multiple fitting appointments, and allows a quick design approval.

Patient comfort & hygiene

The inner structure has an open design for better air circulation and comfort, helping reduce sweating and irritation. The materials are washable with soap and water, simplifying maintenance.

Personalised consistent fitting

Each helmet is individually tailored to the patient’s anatomy while maintaining consistent design features. This ensures uniform quality and reliable protection, adapting precisely to the patient without compromising performance.

The workflow

Upload the 3D scan to the OrthoSolid platform and provide a brief clinical description of the product. Specify the patient’s indication and the required level of support.

We translate the inputs into a digital model. With your feedback, we refine every detail before production. Through this iterative process, we ensure a perfect fit, optimal comfort, and consistent quality.

We produce each helmet using advanced 3D‑printing techniques and high-quality materials to ensure a precise, comfortable fit. After printing, the helmet is assembled with durable straps for reliable support. The finished product is delivered within 5–10 working days, with progress fully trackable through our platform.

Custom products for your specific cases

Fully integrated into our platform, the Custom product workflow is designed for cases that go beyond our Core products. Starting from the product description, our team creates a tailored design, refined through your feedback and iterations until it meets all functional and clinical requirements. Throughout the process, you continue to benefit from all OrthoSolid advantages.